Masonry Tools

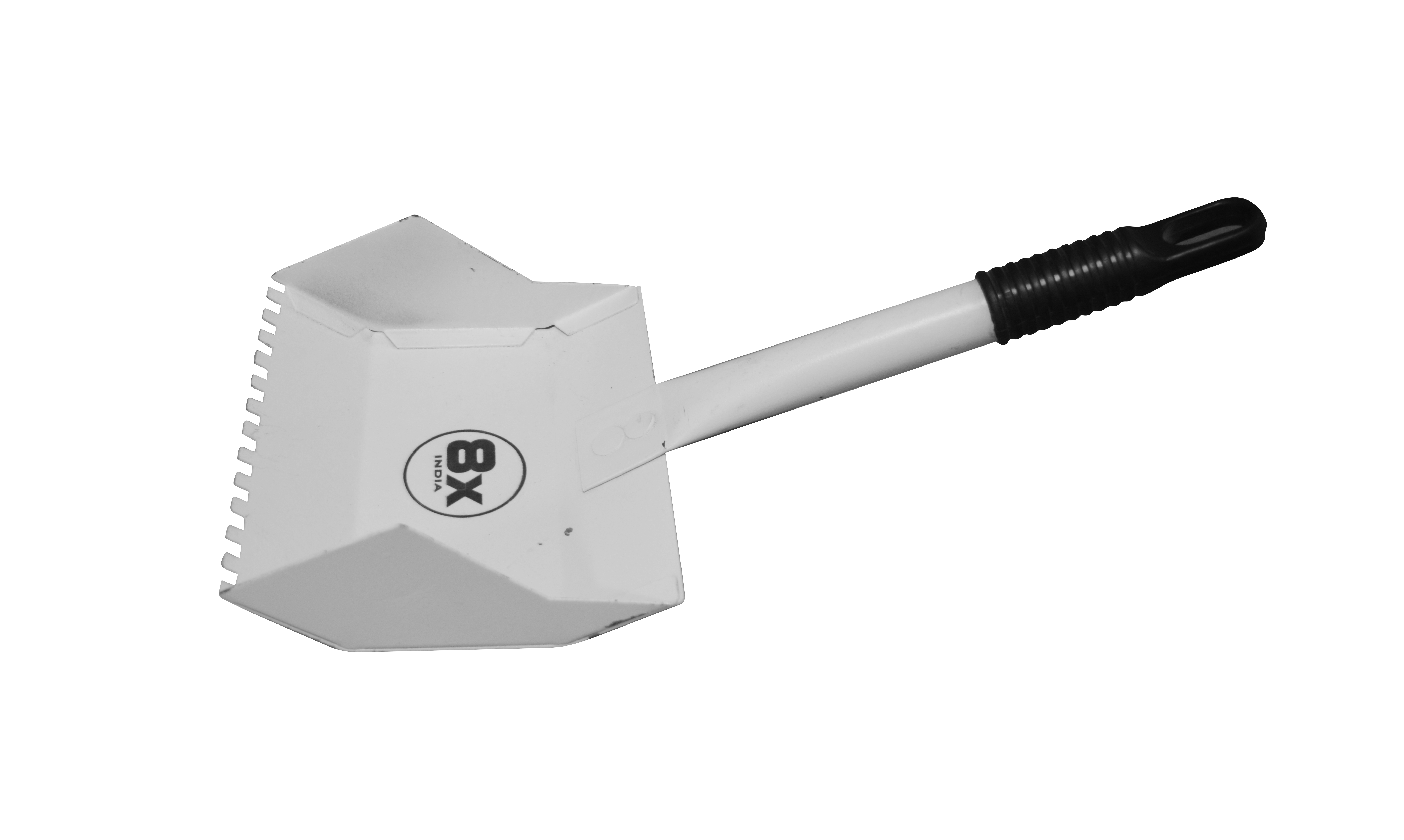

8x Cutting Saw

8x 20-inch hand saw tungsten carbide tipped cutter Blade for cutting Aerated Concrete Bricks and AAC Masonry Cement Blocks size 500mm. AAC blocks, or Autoclaved Aerated Concrete blocks, are a type of lightweight, precast foam concrete building material that offers excellent insulation and constructional qualities. An AAC Block Cutting Saw is a specialized tool designed for accurately and efficiently cutting these blocks to the desired sizes and shapes.

Specifications

- Blade Length: 500mm

- Number of Teeth: 13 Grover & 13 tungsten carbide-tipped

- Cutting Angle: 90 degrees

- Item Weight: 825 Grams

- Amperage: 3.4 Amps

- Special Feature: Ergonomic

Special Features

- Powder Coated

- Rust Proof

- Eco-Friendly

- Ensuring secure and reliable cutting performance over time

- Induction Hardened Teeth: For Long Lasting Sharpness, Smooth and Clean Cuts

- Triple Ground Teeth: For fast and smooth cutting

8x AAC Block Cutting Angle

Autoclaved Aerated Concrete (AAC) block is a low-maintenance precast building material with excellent thermal insulation and durability. The heat-insulating properties of AAC blocks keep the building cooler and prevent outside heat from entering, resulting in significant savings on air conditioning costs.

Specifications

8x 90° Cutting Angle

Provides 90-degree accurate cutting to get a proper rectangular shape blocks which helps to avoid the waste of joining glue.

8x Cutting Stand

8x Cutting stand helps to position the AAC blocks perfectly and helps to cut the blocks in 90 degrees and it helps to avoid floor damage. A Block Cutting Stand is an essential accessory in the construction industry, particularly when working with materials like AAC blocks, bricks, pavers, and other masonry units. This stand is designed to support the material being cut, offering a stable and secure platform that enhances both safety and precision during the cutting process.

8x Rubber Hammer

Provides 90-degree accurate cutting to get a proper rectangular shape blocks which helps to avoid the waste of joining glue. It sounds like you're interested in using a rubber hammer for AAC (Autoclaved Aerated Concrete) blocks. A rubber mallet is often recommended for this task because it can help to minimize damage to the relatively soft AAC blocks during installation or adjustment. These hammers provide sufficient force to position the blocks without chipping, cracking, or causing other damage that might occur with a harder metal hammer. When working with AAC blocks, ensuring that you use the right tools and follow proper techniques is crucial for the stability and integrity of the construction.

8x Notched Trowel

Size:

8x notched trowel is with special stainless steel having high wear resistance and perfect flatness.A notched trowel is used to spread adhesive and a thickness of 3mm. It differs from a regular trowel in that it has notches, usually on two sides of the blade. Running a notched trowel over adhesive or thin-set leaves behind rows of the product.This trowel features a flat blade with notches on one or both sides. The notches can vary in size and shape, depending on the application. In construction, especially when working with Autoclaved Aerated Concrete (AAC) blocks, having the right tools can significantly affect the efficiency and quality of the build. Different types of trowels are used for various tasks associated with AAC blocks

Use:

It's primarily used for applying adhesives or mortar in a way that creates a uniform, ridged surface. The notched design ensures an even spread of adhesive with optimal thickness, crucial for securely fixing AAC blocks.

8x Bucket Trowel

Size:

8x Bucket Trowel is a high carbon steel and spring steel metal with a high-quality powder coating. This bucket trowel is suited for laying joining glue on 4′′/6′′/8′′/9" thickness AAC blocks. Bucket trowels are wide-bladed tools for scooping mortar from a bucket. They are ideal for smoothing mortar on large bricks and blocks. A bucket trowel has a wide, flat blade that's slightly curved at the edges, designed for scooping materials out of containers. An AAC Block Bucket Trowel is a specialized tool designed for use in construction, particularly when working with Autoclaved Aerated Concrete (AAC) blocks. This type of trowel is tailored to assist in applying and smoothing mortar or adhesive when laying AAC blocks.

Use:

It’s used for scooping and spreading mortar or adhesive directly from the bucket, minimizing waste and improving the efficiency of applying material to AAC blocks.

8x Rubber Plastering Trowel

Larger and flatter than most trowels, a plastering trowel is designed for applying and smoothing plaster over large surfaces.

Use:

While not exclusively used for AAC block work, it can be employed for applying a finishing coat over AAC block walls to achieve a smooth, flat surface.

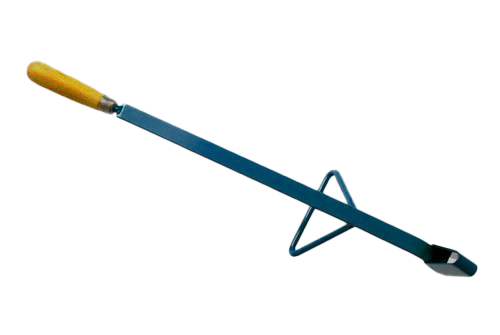

8x Grooving Rod

Using a 8x grooving rod in the context of AAC (Autoclaved Aerated Concrete) blocks is related to the process of creating neat and precise channels or grooves in the blocks, where utilities like electrical wiring and plumbing can be installed. The grooving rod, often a specialized tool, enables workers to carve out these channels without compromising the structural integrity of the AAC block. This is important because AAC blocks are known for their light weight and thermal insulation properties but can be relatively fragile compared to traditional concrete blocks. The grooving process usually involves marking the path where the utilities will run and then carefully using the grooving rod to remove the material along this path. It's a skillful task that requires a steady hand and a good understanding of how deep and wide the grooves need to be to accommodate the utilities while maintaining the structural support necessary for the wall or structure.

8x Box Trowel Fixed

Size:

8x Box trowel is with special steel having high wear resistance and perfect flatness. A Box trowel is used to spread adhesive and a thin set. It differs from a regular trowel in that it has notches, usually on two sides of the blade. Running a notched trowel over adhesive or thin-set leaves behind rows of the product An AAC Block Box Trowel is a specialized tool used in the construction industry, particularly for tasks involving Autoclaved Aerated Concrete (AAC) blocks. This type of trowel is designed to optimize the application of mortar, adhesive, or plaster over AAC blocks, providing both efficiency and precision. Overall, an AAC Block Box Trowel is an essential tool for projects involving AAC blocks, offering the precision and efficiency needed for high-quality construction outcomes.

Key Characteristics

- Blade Design: The box trowel typically has a broad, flat blade. This design allows for the efficient scooping, spreading, and smoothing of mortar or adhesive over a wide surface area, making it ideal for covering AAC blocks quickly.

- Material: Like most construction trowels, the blade is usually made of high-quality steel to resist wear and corrosion. The handle might be constructed from wood, plastic, or a composite material, designed for durability and a comfortable grip.

- Size and Shape: The box trowel's size is optimized for AAC block work, allowing for easy manipulation and control. The edges are often tapered or slightly rounded to prevent gouging the material and to facilitate a smooth finish.

- Handle: Ergonomically designed to reduce fatigue during extended use, the handle ensures that the user can maintain a good grip and control over the trowel, enhancing the precision of the application.

Uses

- Applying Mortar or Adhesive: The primary use of an AAC Block Box Trowel is to apply a consistent layer of mortar or adhesive on AAC blocks. Its broad surface is perfect for covering large areas quickly.

- Smoothing and Finishing: Beyond just application, this trowel is also great for smoothing out the mortar or adhesive to ensure a level surface and to fill any gaps or seams between blocks effectively.

- Versatility: Although it is specially designed for AAC blocks, its characteristics make it suitable for various masonry and plastering tasks, providing versatility to construction professionals.

8x Box Trowel Adjustable

Size:

8x Box trowel is with special steel having high wear resistance and perfect flatness. A Box trowel is used to spread adhesive and a thin set. It differs from a regular trowel in that it has notches, usually on two sides of the blade. Running a notched trowel over adhesive or thin-set leaves behind rows of the product An AAC Block Box Trowel is a specialized tool used in the construction industry, particularly for tasks involving Autoclaved Aerated Concrete (AAC) blocks. This type of trowel is designed to optimize the application of mortar, adhesive, or plaster over AAC blocks, providing both efficiency and precision. Overall, an AAC Block Box Trowel is an essential tool for projects involving AAC blocks, offering the precision and efficiency needed for high-quality construction outcomes.

Key Characteristics

- Blade Design: The box trowel typically has a broad, flat blade. This design allows for the efficient scooping, spreading, and smoothing of mortar or adhesive over a wide surface area, making it ideal for covering AAC blocks quickly.

- Material: Like most construction trowels, the blade is usually made of high-quality steel to resist wear and corrosion. The handle might be constructed from wood, plastic, or a composite material, designed for durability and a comfortable grip.

- Size and Shape: The box trowel's size is optimized for AAC block work, allowing for easy manipulation and control. The edges are often tapered or slightly rounded to prevent gouging the material and to facilitate a smooth finish.

- Handle: Ergonomically designed to reduce fatigue during extended use, the handle ensures that the user can maintain a good grip and control over the trowel, enhancing the precision of the application.

Uses

- Applying Mortar or Adhesive: The primary use of an AAC Block Box Trowel is to apply a consistent layer of mortar or adhesive on AAC blocks. Its broad surface is perfect for covering large areas quickly.

- Smoothing and Finishing: Beyond just application, this trowel is also great for smoothing out the mortar or adhesive to ensure a level surface and to fill any gaps or seams between blocks effectively.

- Versatility: Although it is specially designed for AAC blocks, its characteristics make it suitable for various masonry and plastering tasks, providing versatility to construction professionals.

8x Corner Trowel

Available in internal and external variants, corner trowels have an L-shaped blade designed to fit into corners.

Use:

They are used for shaping and smoothing mortar or plaster in the corners of AAC block walls, ensuring a clean, professional finish.Each of these trowel types is designed to perform specific tasks more effectively, contributing to the overall success of AAC block construction projects by ensuring proper adhesive application, and precision in material placement, and finishing.